Baghouse Design Calculations

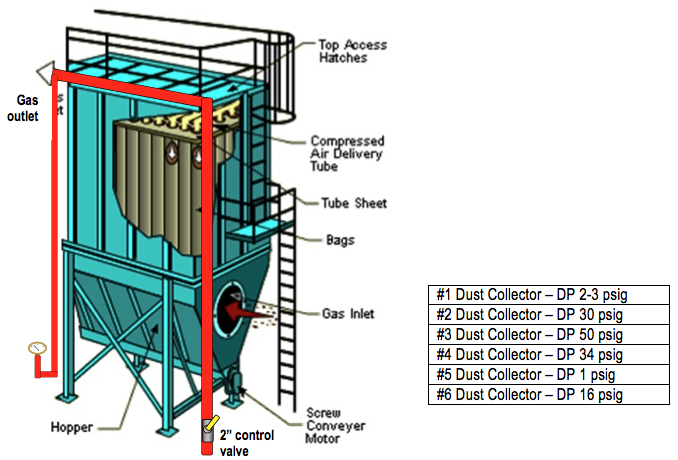

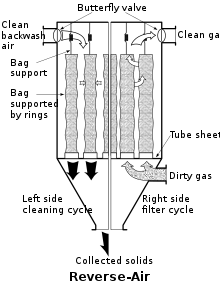

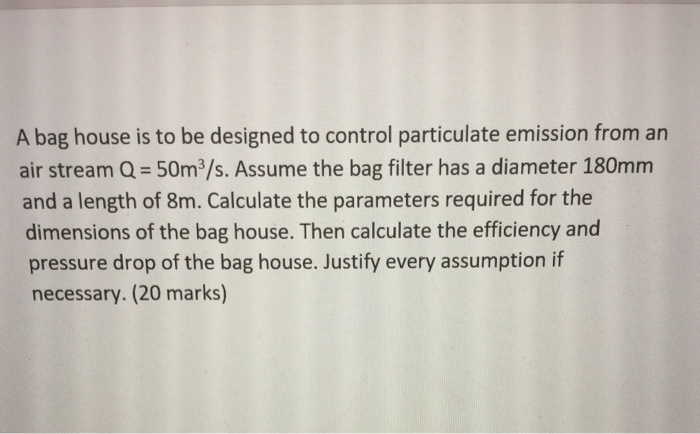

Baghouse design calculations. At SDC we have the Engineering expertise to design your dust collector to suit your needs and provide the structural calculations along with it for No Extra Charge. Calculate the number of bags required in a baghouse for a given process flow rate 4. Identify and describe the main components of a typical baghouse.

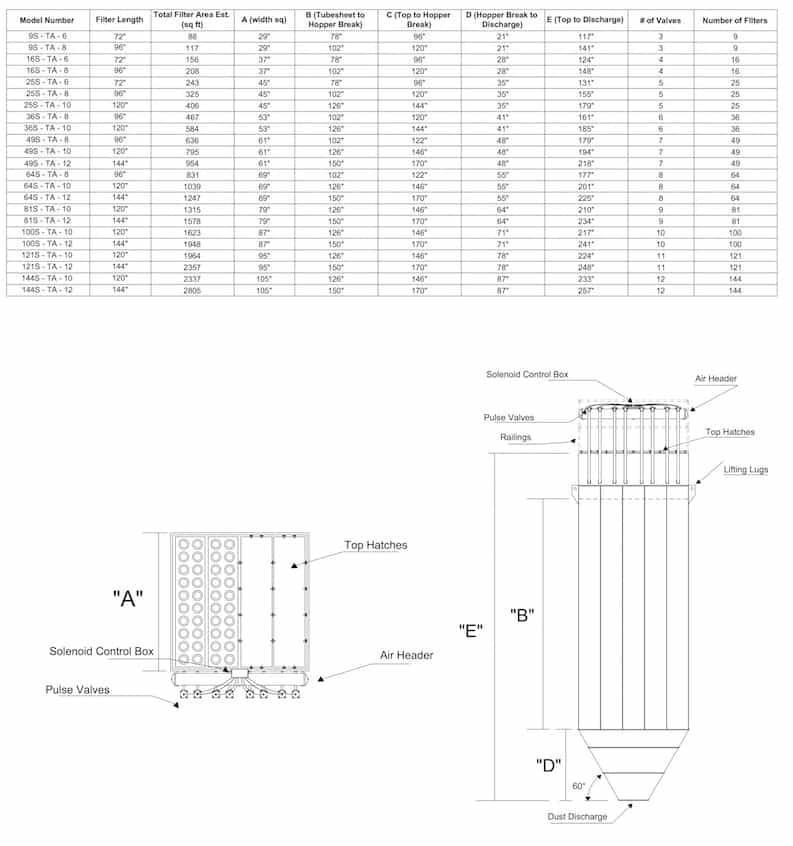

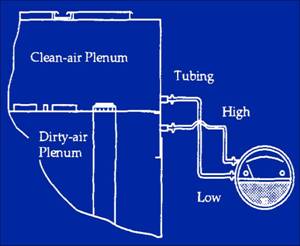

Design Considerations Interstitial Velocity Upward velocity of airparticulate between filters inside baghouse Measured in fpm feet per minute Determined by dividing airflow cfm by cross sectional area of filter housing less bag area Not to be confused with can velocity EXAMPLE. Typical values are about 4 Hz for frequency and 2 to 3 in. Total cloth area 90767 ft2.

Then Click on Calculate To Find the Cloth Area. Structural software to design and. During this second lecture in the Baghouse 101 series Bill Kurz of Sly Inc.

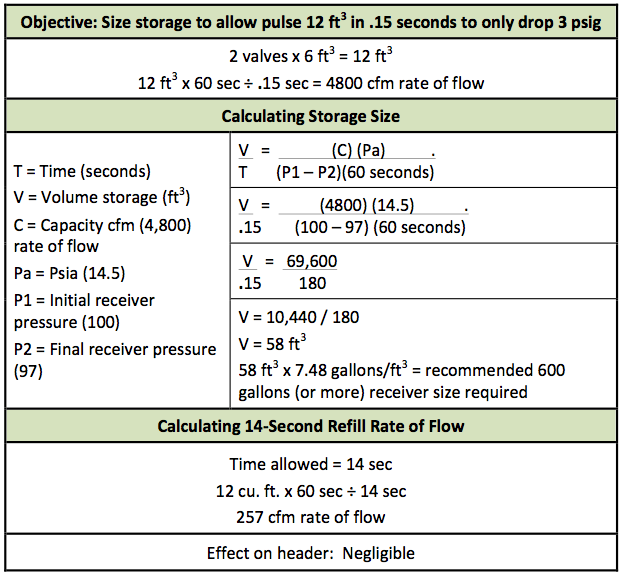

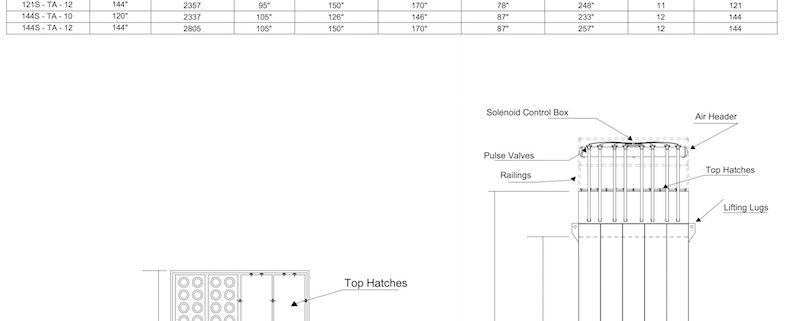

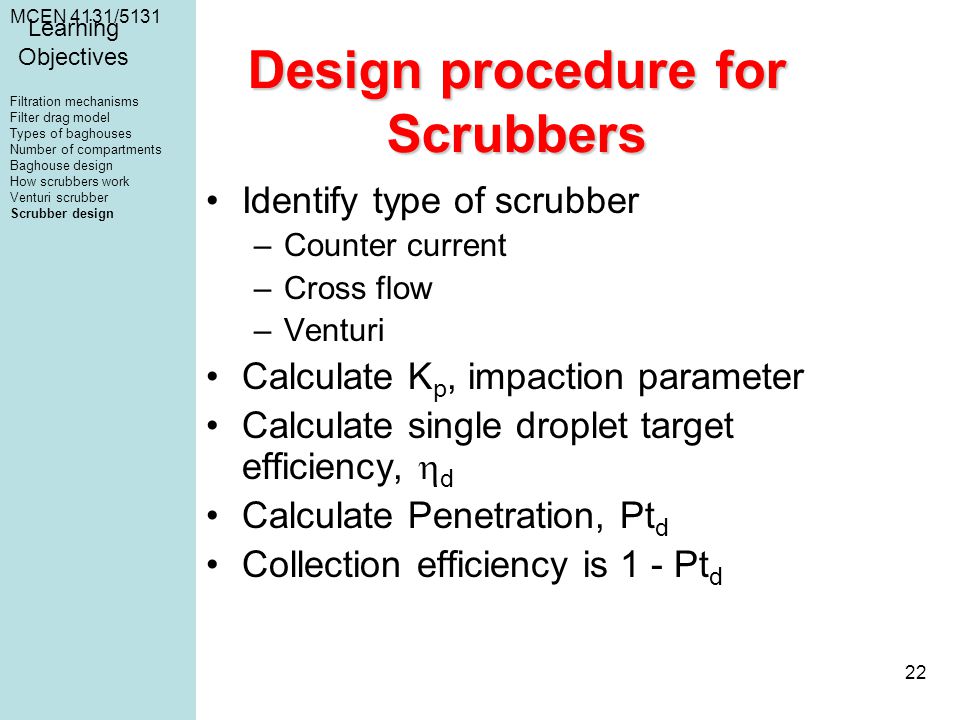

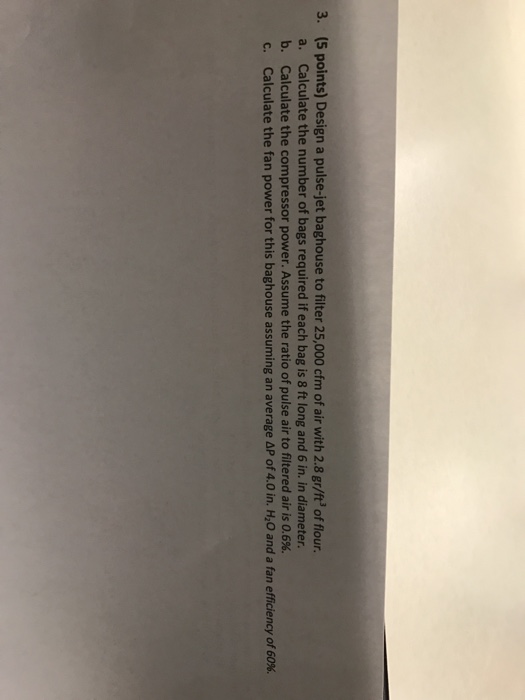

Calculate the gross air-to-cloth ratio the net air-to-cloth ratio and the netnet air-to-cloth ratio for a baghouse design. We continue from our last article where we reviewed the 4 key design variables of airflow in CFM static pressureresistance air velocity and air to cloth ratio. First calculate the total cloth area of your collector by calculating the total filter area of each filter bag diameter x 314 x length 144 for number of inches in a square foot filter cloth area and then multiply that figure by the total number of bags in the collector.

Baghouses are designed by considering a number of variablespressure drop filter drag air-to-cloth ratioand collection efficiency. Filtration area per bag. Cloth Area Sq.

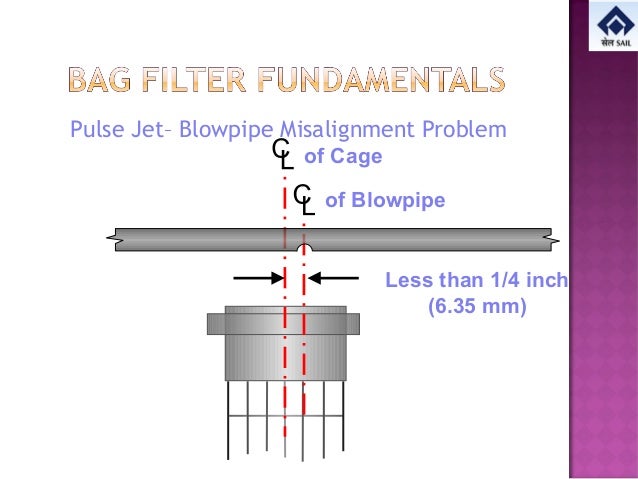

Think back to high school math and the circumference of a circle. For ampli-tude half-stroke4 The tension is set to about 2 lbin. 8000cfm air required for dust control.

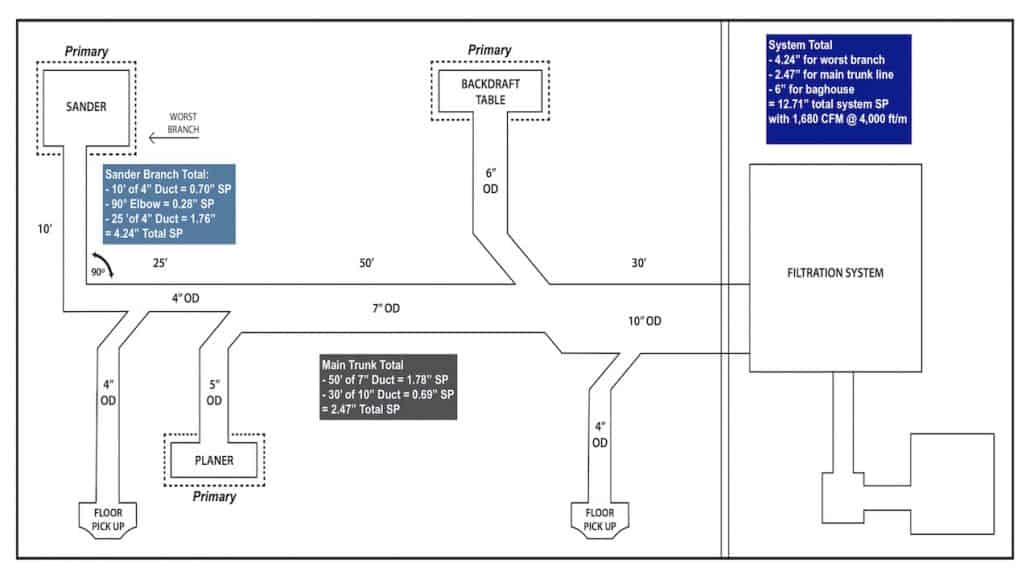

When we are finished we will know exactly how large of a baghouse we will need including how much filter area required along with our fan output x. The tension is set when bags are installed.

Total CFM 297716 ft3min.

8000cfm air required for dust control. During this second lecture in the Baghouse 101 series Bill Kurz of Sly Inc. Then Click on Calculate To Find the Cloth Area. Design Considerations Interstitial Velocity Upward velocity of airparticulate between filters inside baghouse Measured in fpm feet per minute Determined by dividing airflow cfm by cross sectional area of filter housing less bag area Not to be confused with can velocity EXAMPLE. Now we can begin calculating these variables for our new dust collection system. If you know the diameter of the bag multiply this diameter by 314 to get the circumference. Total cloth area 90767 ft2. Well-designed and operated baghouses have been shown to be capable of reducing overall particulate emissions to less than 005 gm 3 0010 grft 3 and in a number of cases to as low as 0002 to 0011 gm 3 0001 to 0005 grft 3. The tension is set when bags are installed.

Typical values are about 4 Hz for frequency and 2 to 3 in. We continue from our last article where we reviewed the 4 key design variables of airflow in CFM static pressureresistance air velocity and air to cloth ratio. Enter Bag Diameter π Length of Cages of Bags 144 sq. Calculate the gross air-to-cloth ratio the net air-to-cloth ratio and the netnet air-to-cloth ratio for a baghouse design. The first two parameters are part of the baghouse design and generally are not changed easily. Estimate the cloth area needed for a given gas process flow rate 3. Of bag circumference when bags are installed.

.jpg)

Post a Comment for "Baghouse Design Calculations"