Install An Air Lubricator In A Pneumatic System

Install an air lubricator in a pneumatic system. Using a lubricator depends on what your system needs downstream. MGA Controls have provided information regarding the pneumatic lubricator function. Though please be aware that theyre only a rough guide.

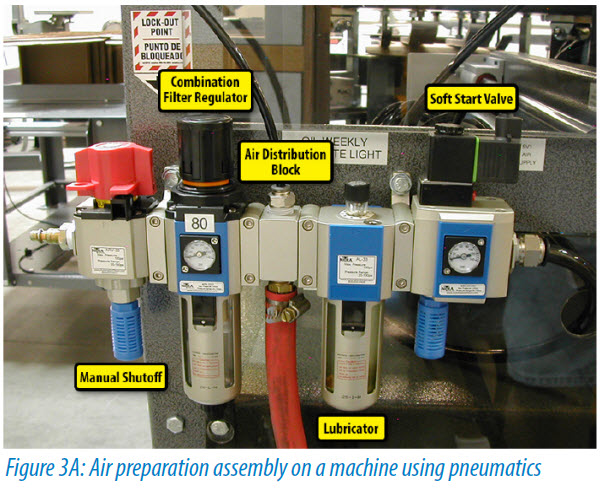

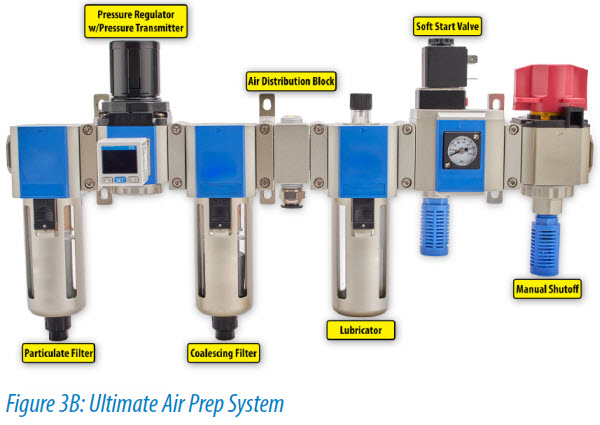

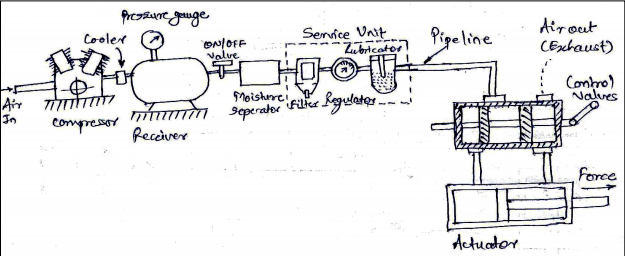

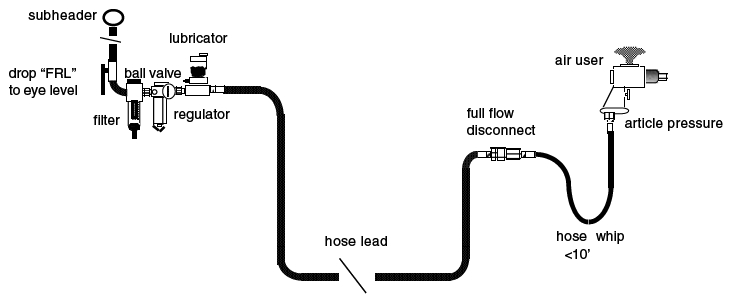

As a general rule a pneumatic systems order of installment is in this order. To optimize the pneumatic system and reduce cost only treat air where air. FRL System Because airline filters remove contaminants from pneumatic systems they prevent damage to equipment and reduce production losses due to contaminant-related downtime.

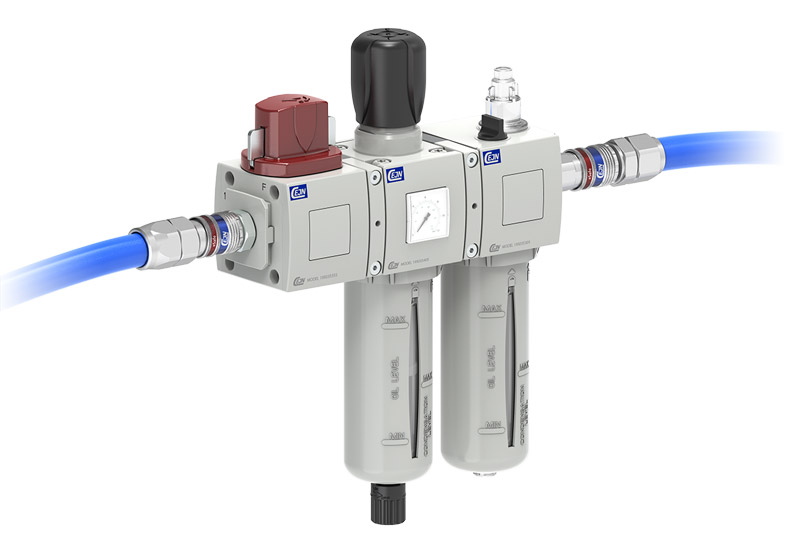

If they arent self-lubricating a lubricator should also be installed in the system. Add a lubricator to the system to provide downstream components with a constant supply of oil lubrication by introducing a small amount of oil to the compressed air stream. Consider the consequences first.

A lubricator should always be the last element in an FRL Filter-Regulator-Lubricator unit. Should you install a lubricator anyway perhaps just to play it safe. While each construction or rental air system tends to be unique it is very important to pay close attention to it.

If they arent self-lubricating a lubricator should also be installed in the system. Compressor filter regulator and then a lubricator. Miniature 14L Series 14 Inch Compact 16L Series 14 thru 12 Inch Standard 17L Series 38 thru 34 Inch Hi-Flow 18L Series 34 thru 1-12 Inch Lubricator Selection 1.

Pulling Money Out of Thin Air Feb. A pneumatic lubricator sprays micro-particles of lubricator oil into the airflow to provide fluent lubrication. Machine Design Hydraulic and Pneumatic Filters Nov.

The device injects a stream of oil into the airline ensuring they perform at the optimum level at all times. In most typical air systems a lubricator is installed right after the compressor and it mists the airflow with oil on its path to the tool.

Advances in seal material have minimized their importance.

NANPU 38 NPT Air Filter Pressure Regulator Lubricator Dryer Gauge Kit WaterOil Trap Separator 3 in 1 Twin Unit. As a general rule a pneumatic systems order of installment is in this order. To optimize the pneumatic system and reduce cost only treat air where air. Machine Design Hydraulic and Pneumatic Filters Nov. MGA Controls have provided information regarding the pneumatic lubricator function. The size and condition. Lubricators use an adjustable visual indicator to measure the amount of oil downstream and have an oil. You should also consider providing documentation with your machine that clearly states the correct setting for the device the maintenance schedule to check oil level and a recommendation for the correct oil to be use. In most typical air systems a lubricator is installed right after the compressor and it mists the airflow with oil on its path to the tool.

FRL System Because airline filters remove contaminants from pneumatic systems they prevent damage to equipment and reduce production losses due to contaminant-related downtime. Add a lubricator to the pneumatic system to provide downstream components with a constant supply of oil lubrication by introducing a small amount of oil to the compressed air stream. Compressor filter regulator and then a lubricator. Compressed air enters the inlet port and passes over a. To optimize the pneumatic system and reduce cost only treat air where air. Determine maximum allowable pressure. If they arent self-lubricating a lubricator should also be installed in the system.

Post a Comment for "Install An Air Lubricator In A Pneumatic System"